The first and only residential pressure sewer pump with a 20 year life* and zero scheduled maintenance.

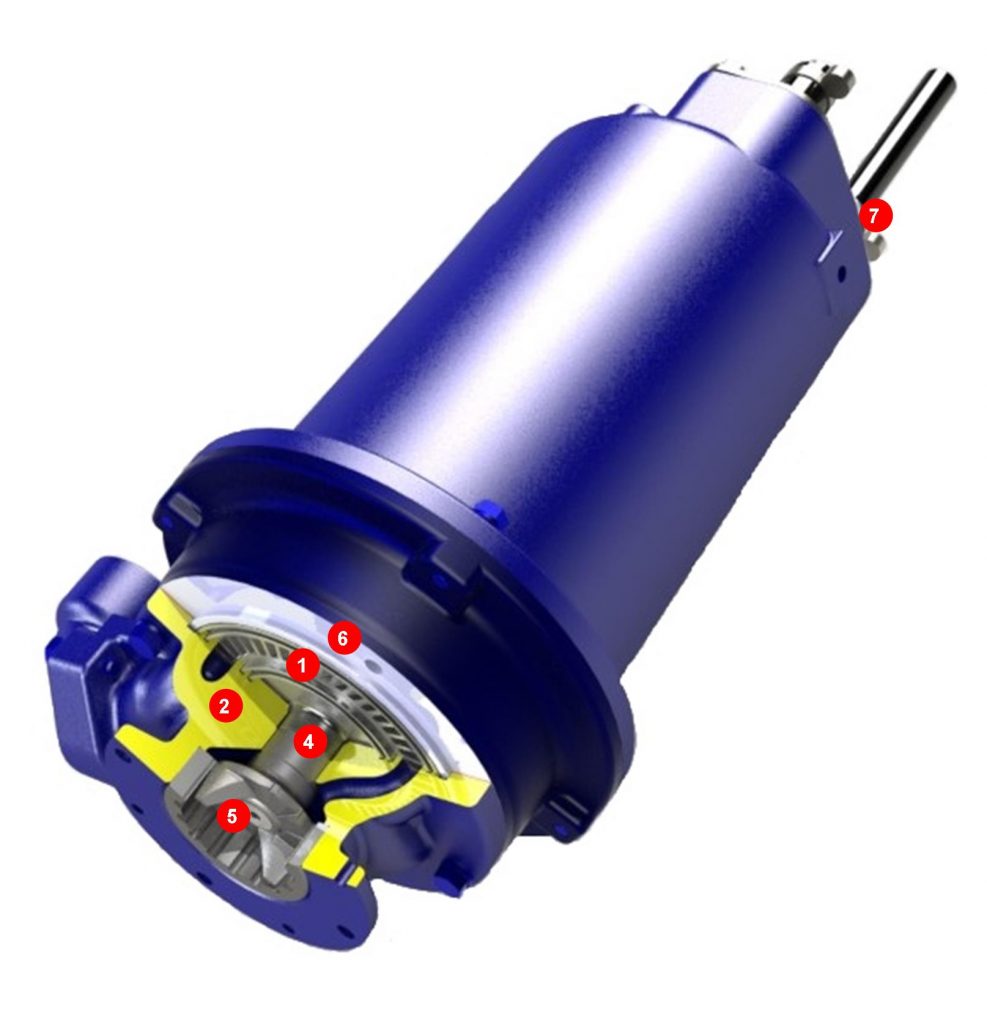

Construction details

1 Abrasion Resistant Impeller. Proprietary Aerospace infusion coating technology; a stainless steel turbine impeller with multi vane design, steep curve and aerospace coating resists abrasion from sand, grit and hard particles to provide double the life of conventional Progressive Cavity pumps. This coating was used to protect the high speed turbine components in Blackhawk helicopters during the ‘Desert Storm’ conflict.

2 Abrasion Resistant Dual Channel Volute. Has a propriety aerospace infusion coating engineered to resist abrasion for the whole of life. The Dual Channel Volute balances load on shaft which increases grinding ability.

3 Steep Pump Curve. The steep pump curve enables smaller diameter pipework and greater control over system pressure, with capability up to 80 metres or the flexibility to set maximum limits at lower pressures providing full network control and protection.

4 Shorter Shaft. A shorter shaft enables a closer tolerance on the cutter with tighter clearances, eliminating side-to-side deflection and jamming (as seen with progressive cavity

pumps) while increasing the life of the mechanical seal.

5 Slicerator. A smaller cutter and grinder radius with tighter clearances maximises cutting force for grinding fibrous materials and all modern textiles to eliminate jamming.

6 Silicon Carbide Seal. A Silicon Carbide Mechanical Seal with vented case reduces working pressure to increase seal life. Hydraulic passages and pump-out vanes protect from

stringy debris and abrasive media for longer life.

7 Cable Plug. A hermetically sealed cable connector, ensures that no water will penetrate into the motor

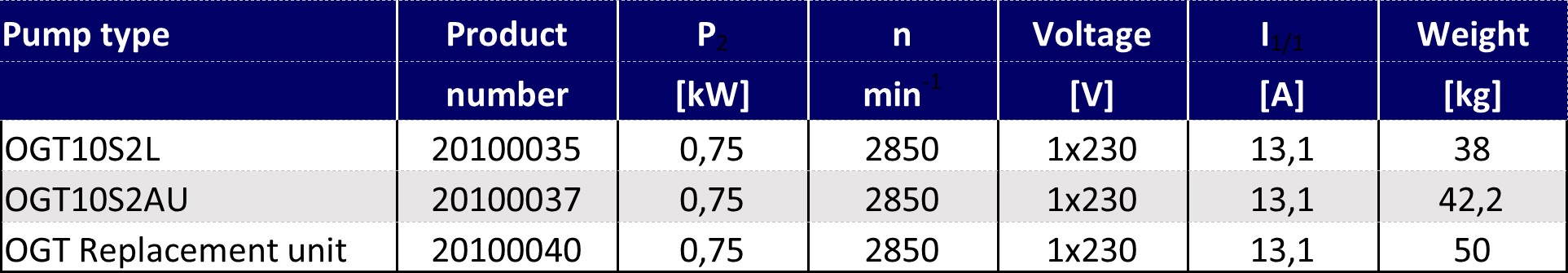

OGT Technical details

Replacement pump.

The OGT grinder pump is also supplied as a complete replacement pump for Progressive Cavity grinder pump installations. PLUG & PUMP